It all started way back in college in the early 90’s…

I was DJ’ing, going out dancing with my friends, and vintage was all the rage. But all the cute tops and dresses in the thrift shops were huge on me and hung awkwardly on my narrow, forward shoulders.

Being the crafty maker type, I borrowed my best friend’s sewing machine, altered away, and created a personalized wardrobe that fit. For the first time in my life, I truly felt like myself in my clothes. I was hooked.

Fast forward to 2013. My body is “maturing”. Things are sitting a little lower and I’ve got new curves. Fit is affecting the way I feel about my body more than ever.

Thanks to many years as a software engineer slumped over a computer, my upper body had transformed into a crumpled mess. Ready-to-wear clothes choked me at the neck and sleeves pinned my arms like a straight jacket. Fast fashion and poor quality had already completely turned me off from clothes shopping. The fit headaches weren’t making it any more fun.

Help! Sewing machine to the rescue!

I set out to solve my fit problems by sewing my own wardrobe. Unlike my college years, I now had the power of the internet to help. Online, I discovered this inspiring new movement of independent pattern designers and global community of sewists just like me! Yes, I could do this!

As I pushed to get a better fit, my sewing hobby transformed from a fun, intuitive challenge that I could solve with my hands into a demoralizing, abstract math puzzle. Hello muslin spirals and hacked taped pattern chaos.

I thought maybe what I needed to conquer my fitting woes was a dress form. After a bunch of research, I realized commercial designers were using standard forms to fit an “average” person – that was NOT going to solve my problem because the reason things don’t fit me is that my body is not average. Nobody is an average. I realized I needed a “body double”.

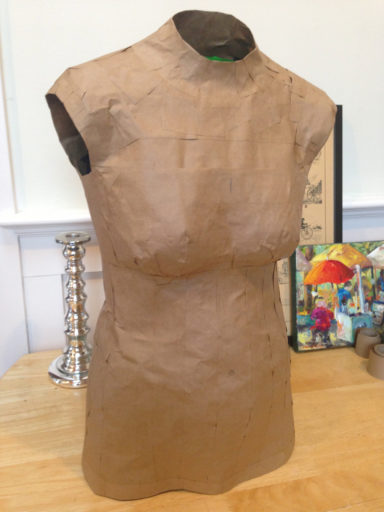

Again, the existing solutions were disappointing: cast your body (too involved), custom form from measurements (too expensive, inaccurate), padded standard form (also inaccurate) or paper/duct tape forms. I went with the cheapest option – paper tape – and while it was a total eye opener for me in terms of fit and body acceptance, it was a royal pain to make. And it lacked many critical features like being pinnable.

What I really wanted was a thoughtfully designed custom tool that would inspire me to create beautiful things, not a lumpy, frustrating paper mache project.

My nerd-side kicked in. When I was an engineer at Apple, I made technology work for creatives. Why couldn’t I make technology work for every day sewists like me to tackle fit?

I consulted my husband Nathan who, lucky for me, happens to be a mechanical engineer. We cobbled the tech together on weekends and in a month, we were able to generate a 3D model of me using photos taken with an iPhone. We cut the first “mini me” out of that pink insulation foam you get at Home Depot. Indeed, it could be done.

After leaving the Bay Area for Colorado, the custom dress form project kept calling to us. Two years later in 2017, we finally made the leap of faith. It was time to quit our tech jobs so we could devote all of our energy to empowering makers like you.

Beatrice was born!

Happy Making!

❤️Alison and Nathan